The "Wooden Wonder" (or "Timber Terror") of World War II was the De Havilland Mosquito, a highly successful aircraft, made primarily from wood, used in both fighter and bomber configurations. The fact that it competed effectively with aluminum-based aircraft shows that it is a mistake to discount wood as an important resource for the USE.

Wood, of course, is a very familiar material to the down-timers, but that doesn't mean that they have nothing to learn from the up-timers. The latter can offer advice as to where to find valuable tree species not already in European use, new wood products, new uses for existing products, new equipment for processing wood, and more sophisticated forestry management techniques.

The use of wood is pervasive in seventeenth century society. In consequence, changes in "wood technology" or forest management can create unpleasant surprises for the up-timers.

For example, the up-timers might want to limit the cutting of trees to "sustainable growth" levels. Yet one of the goals of the Swabian peasant rebellion of 1525 was to restore "the right to freely collect building materials and firewood from the village's forests," unless those rights "had been specifically sold off." (this was article five of "The Twelve Articles") (Sands 31; Handisides)

Another example is that we might want to build more modern sawmills, which process wood faster, with less labor and less waste. But in England, the first sawmills were attacked by mobs of handsawyers, who feared that the new equipment would deprive them of their source of living. Sawmills weren't accepted in England until 1788. Sawmills were quickly accepted in America because where there was a labor shortage (and plenty of timber)(Lillard, 23; Cox 14; Pike 39).

We might also want to protect the trees which are most suitable for shipbuilding—it will be a while before we are building all-iron ships. But Pike says that the eighteenth century British "broad arrow" policy (marking selected pine trees to reserve them for use as ship masts, and punishing scofflaws) "did more to cause the American Revolution than the Stamp Act and the tea tax put together." (Pike 48)

The up-timer Gordon Alexander (1938-) is a former employee of the USDA Forest Service. (If he were employed in West Virginia, it was most likely at the Monongahela National Forest.) While he has only a high school diploma, the Grid says that he has taken "lots of specialized courses from the Graduate School of the Department of Agriculture." The USDA Graduate School offers certificates of accomplishment in Natural History Field Studies, Horticulture, Landscaping, and other subjects. The available courses include tree identification, but not forestry management per se. Hopefully, he learned that on the job.

The Grid doesn't reveal Gordon's job title. The most common positions at the Forest Service are forestry technician (7457), forester (5287), civil engineering technician (1771), clerk/administrative assistant (1599), and civil engineer (1073). Nowadays, a forester usually will have a suitable college degree, but that might not have been true when Gordon started. A formal college education is not required for a technician, but some have associate degrees.

Phil Jenkins is a young up-timer (14 as of the RoF) with interests in "forestry and forest management." David Caine is a contractor whose company trimmed trees for the power company. Grantville also has biologists and gardeners.

Grantville residents could conceivably have taken forestry courses in West Virginia. West Virginia University (Morgantown) has an accredited professional forestry degree program, while Glenville State College (Glenville) has a forest technology program. The Grid identifies college graduates, but not the schools attended.

There are articles on trees, woods and forestry in the Grantville encyclopedias. I have checked the catalogue of the Mannington Public Library (which is the model for the Grantville one), and it has a number of useful books. There are at least seven guides to trees (they concentrate on American trees, of course) and at least two on West Virginia logging, Clarkson's Tumult on the Mountains and Blackhurst's Of Men and a Mighty Mountain.

It is somewhat more difficult to determine how much forest is in the Ring, and which species of trees it contains.

West Virginia, in 2000, was 76% timberland. There were eight state forests; the nearest to Mannington was the Coopers Rock State Forest in Monongalia and Preston Counties.

Grantville is in Marion County, whose timberland, in 2000, fell into the following stand-size classes: 99,300 acres of saw-timber, 17,600 pole-timber, 13,100 saplings and seedlings; total, 130,000 (65% land area). (Table 68). In terms of forest-type, there were 80,700 acres of oak/hickory, 7,200 of elm/ash/red maple, and 42,000 of northern hardwoods (Table 69).

The 2002 Census of Agriculture profile for Marion County reported that its 50,153 acres of farms included 5,887 acres of pastured woodland and 11,786 acres of unpastured woodland (figures were a little lower for 1997). Marion County has a total land area of 310 square miles (198,400 acres). The Ring has a diameter of six miles, so it has an area of 28.26 square miles (18,100 acres). If it has its fair share of the county's farm property, then it should include at least 6,500 acres of farmers' woodland. And there will be trees on residential plots, and in public areas, too. And perhaps also some outright timberland.

In Coopers Rock State Forest, about half the forest cover, found on dry ridge and upper slope areas, is dominated by trees belonging to the oak-hickory group (e.g., white oak, black oak, northern red oak, scarlet oak, chestnut oak), and are associated with yellow poplar, blackgum, sugar and red maples white and green ash, elms, basswood, cucumber magnolia, and occasional bech, black cherry, black walnut and eastern hemlock. The other half, found on stream bottoms and lower slopes, and in "moist coves," is the yellow poplar group (yellow poplar, eastern hemlock), associated with cucumber magnolia, black cherry, northern red oak, red maple, ash and black lotus. (Coopers Rock State Forest: Forest Resources Management Plan)

The state has an active "urban and community forestry" program. Their website (wvforestry.com) says that red oak, sugar maple, hackberry, white ash, scarlet oak and hophornbeam are good for street tree use, and that serviceberry, black gum, hornbeam, swamp white oak, tulip tree and river birch are good for landscape use.

There was a state tree nursery in West Columbia WV, from which West Virginia landowners could purchase "urban green units" (minimum order of two units, 25 trees per unit) of white pine, Scotch pine, red pine, Virginia pine, Norway spruce, Japanese larch, Douglas fir, European black alder, black locust, black wlnut, Chinese chestnut, chinquapin, "Streamco P. Willow cuttings," red oak, chestnut oak, white oak, American chestbut, and butternut.

There are several tree farms in Marion County (e.g., the 378 acre Crawford Tree Farm), but none, so far as I know, that would have been captured by the Ring of Fire. Of course, Grantville residents may have purchased trees from these tree farms.

Deforestation—the loss of forest cover—has been a recurring problem in world history in general, and in Europe (and its colonies) in particular. The principal cause of deforestation was the clearing of land for farming. However, the use of wood as a fuel and building material was also important.

So far as early seventeenth century forest cover is concerned, it is a mistake to treat Europe as a monolithic entity. At one extreme, we have Poland, Russia, Norway (part of the Kingdom of Denmark) and Sweden (including Finland), which export timber to less fortunate countries. At the other extreme, we have Spain (including Portugal), Italy, the Netherlands, Denmark proper, and to a lesser extent England, which are largely denuded, and thus heavily dependent on the Baltic timber trade. France and Germany are in-between; there are still significant forests, but those countries have been forced to take various conservation measures, and also to import some wood. (Elliot, 11-12)

Cox says that in the late seventeenth century, only one-eight of England's original forest remained. (Cox 26). According to Clark, the price of firewood was 7.81 shillings per cord in 1540, 16.94 in 1570, 18.62 in 1600, and 26.09 in 1630. Timber prices were anomalously low (3.11 shillings per cubic foot) in 1630; the price was 8.00 in 1631, as compared to 2.87 in 1600.

In France, forest area declined from 35% at the beginning of the sixteenth century, to 25% in the middle of the seventeenth century. (Sands 32)

In 1602, Denmark banned the export of oak; they needed it for their own navy. This forced the British (and Dutch) to rely primarily on timber from Konigsberg and Danzig. (Tossavainen sec. 6.2.1) By 1628, oak was once again a Danish-Norwegian export, but the trade in large timbers (e.g., for masts) was forbidden in 1640 (6.5).

The 1911 Encyclopedia Britannica (EB11) reports the forested area, relative to total area, for each European country. Bear in mind that it is likely that these values are mostly lower than those which prevailed in the early seventeenth century, except that there was some reforestation in the nineteenth century. In particular, 1911 Norway is probably lower than in the seventeenth century, and Greece, Italy and Spain higher. This probably reflects the depletion of Norwegian timber by exports to England, and the recovery of southern European forests thanks to diminished naval and merchant fleet building.

The large-scale transportation of timber down the Rhine, from sources in the Black Forest, Alsace, and around Lake Constance, began around 1250. The trees were cut in the winter, when sap was low and the logs could be dragged across ice or snow, and then rafted downstream come spring.

In the 1650s, the Dutch got their timber primarily from Norway (about 125,000 "lasts"), but the Rhineland was also a source (about 22,000 lasts). In the following decade, their Rhineland imports climbed to over 60,000 lasts. (De Vries, 427)

Deforestation was certainly a problem in parts of seventeenth century Germany. In 1662, John Evelyn wrote that in Alzey, Germany, near Worms, the inhabitants were so "miserably distressed for wood," as a result of their own destructive habits, that "they were reduced to make use of straw for their best fuel." (Evelyn XXI 4). But Thuringia, at least, is still heavily wooded. ( 1632, Chaps. 11, 51).

In general, deforestation in Germany (especially in the south) wasn't as severe as in England. The literature on the American colonies refers repeatedly to how clueless English settlers had to seek forestry guidance from those of German as well as Scandinavian descent. For example, discussing American architecture, Cox says, "Log [cabin] construction techniques were introduced by Europeans from more heavily forested areas—Germans, Finns, Swedes. . . ." (Cox 8; Lillard 15) Later, referring to the production of tar and turpentine, Cox states, "Authorities tried to increase efficiency by sending knowledgeable Germans, Poles and Scandinavians into the woods. . . ." (17) Fire-clearing, and communal logrolling bees, were introduced to Pennsylvania by Swedes, Finns and Germans. (10) Axwork was taught by Swedes and Germans (Lillard 19). The Germans wouldn't have had this expertise if they didn't have forests to acquire it in.

The principal forests of Germany include the Thuringerwald in Gotha, the Schwartzwald (Black Forest) in Baden-Wurtttemberg, the Odenwald in Hesse, the Spessart between Aschaffenburg and Wurtzburg, the Baierischerwald near Bohemia, the Kranzberg near Munich the Frankenwald in northern Bavaria. German trees included spruce, silver fir, Scotch pine, birch, beech, and oak ("Forests and Forestry", EB11).

To botanists, trees are either gymnosperms (plants with needle-shaped leaves, bearing cones and naked seeds) or angiosperms (plants with broad leaves, which produce seeds encased in a seed coat). For commercial purposes, trees are divided into two major classes: softwoods and hardwoods. The softwoods are usually gymnosperms (conifers) and the hardwoods are usually angiosperms (broadleaved trees). There are, however, tropical angiosperms with soft wood, and there are conifers whose wood is quite hard (e.g., pitch pine).

Within a given tree, the wood is differentiated into the central heartwood and the peripheral sapwood. The average commercial log is 25-30% sapwood, so we would prefer not to waste it, if that can be avoided. Heartwood is more strongly colored than sapwood, and so, for ornamental use, heartwood is usually preferred (although sapwood can be stained). Sapwood and heartwood are usually of equal weight if they have the same moisture content. Sapwood is not significantly inferior in strength to heartwood of the same moisture content and density. Unfortunately, sapwood is usually more vulnerable to attack by fungi and insects than heartwood. So durability is a problem if the wood is to be used outdoors, or elsewhere where the risk of attack is significant. One consolation is that sapwood is more readily impregnated with preservatives. (Desch, 51-56).

The branch of a tree bends in response to gravity, putting the top into tension and the underside into compression. If the trunk of a tree leans, the wood is tensed on one side and compressed on the other. The living tissues of a wood react to stress by forming lignin-rich tension wood on top (hardwoods), or cellulose-rich compression wood underneath (conifers). These reaction woods are usually considered undesirable. However, for skis, compression wood had the advantages of drying faster without warping, and of not sticking to thawing snow. (Wikholm)

In temperate climates, cut wood displays annual growth rings. The early (spring) wood is softer and lighter, while the late (summer) wood is harder and darker. (The late wood contains more wall material.) The difference is pronounced in some species, subtle in others. (Desch 16, 26; EB11/Timber) In the seventeenth century, it was already known that the age of a tree could be determined by counting the number of rings (Evelyn), and of course one could readily deduce that a tree with a low density of rings was growing rapidly. Strength is related to the growth rate; there is a rate at which strength is optimized. (Desch 56)

To a botanist, a tree is mature when it starts producing seed. The white cedar can drop cones when it is merely six years old, but it is most prolific when it is over seventy five years old. Likewise, a white pine can bear cones at five years old, but good production comes several decades later. The paper birch, a deciduous tree, starts seed production at age fifteen. (Error! Hyperlink reference not valid.) Oaks don't produce acorns until they are twenty years old.

To a logger, a mature tree is one which can be cut into merchantable timber, which usually means that it is over thirty centimeters diameter (the smallest base diameter for lumber) at "breast height" (1.3 meters). A "pole" has a diameter of at least seven centimeters, and can be used in paper production. A tree is considered "overmature" when decay becomes substantial. "Snag" is deadwood which is still standing (firewood in the eyes of neighborhood farmers, but an important wildlife microhabitat so far as environmentalists are concerned). (Wikipedia).

It isn't surprising that wood is a useful structural material because the successful growth of forest trees is dependent on the physical properties of wood. From an engineering standpoint, wood is a bundle of cellulose fibers. If stretched along the grain, it does quite well (the tensile strength of spruce is about 17,000 p.s.i.). On the other hand, it is weak if compressed in the same direction, which causes the fibers to buckle (for spruce, the compressive strength is 4,000-5,000 p.s.i.). The lateral (across the grain) strength of wood is rather low, whether it is compressed or tensed (a few hundred p.s.i.).

Wood is also quite stiff (stiffness is the resistance to bending); it has a Young's modulus of about two million p.s.i. Both the tensile strength and stiffness of wood compare favorably, on a by weight basis, to that of steel.

Generally speaking, the denser the wood of a particular tree, the greater its average strength (Desch 147). The specific gravity (density relative to that of water, which is 62.4 pounds per cubic foot) of the actual wood material is actually about 1.4 or 1.5. Timber floats because it contains a lot of air, and some timbers have more air space than others. The specific gravity of timber varies a great deal:

balsa 0.1

spruce 0.45

oak 0.7

lignum vitae 1.1

(Gordon, 157)

While an increased density has a favorable effect on strength, it has an unfavorable one on transportabity; the denser the timber, the less floatable it is.

The principal dimension of lumber ideally runs parallel to the grain. Any slope reduces the bending strength, stiffness and impact resistance. A slope of only 1 in 25 reduces bending strength by 4%, stiffness by 3%, and impact resistance by 9%. (Desch 65).

Wood contains water and, the lower the moisture content, the greater the strength. Air-dry wood (moisture content about 12%) has about twice the strength in bending and endwise compression as it did prior to seasoning, and if kiln-dried (moisture content 5%) the factor is threefold. (Desch 168-9).

A tough wood is flexible; it bends instead of breaking. The Encyclopedia Americana "Wood" article (EA/Wood) notes that hickory and ash are flexible while hemlock and pine are brittle. However, a tough wood must also be strong. EA/Wood says that elm and hickory are both tough. High moisture content increases toughness. (Desch 168-9)

Hardness is also different from strength, and it is something of a mixed blessing. The harder woods are less likely to be scratched or dented, but they are harder to saw across the grain. EA/Wood classifies twenty nine woods according to their hardness.

Wood is split by cleavage along the grain, and EA/Wood gives information on the relative splitting qualities of eighteen woods.

The durability of a wood is its resistance to decay caused by fungi and bacteria. EA/Wood classifies forty seven woods according to their durability. Woods can be treated with preservatives; the tradeoff is between a cheap wood of low natural durability treated periodically with preservative, and an expensive wood of high natural durability.

In general, these decay organisms require warmth and moisture (wood moisture content over 20%) to do their work. That is one reason for seasoning (drying) wood. Good ventilation also helps to inhibit fungal growth (Desch 248).

Color is of course relevant to the marketability of ornamental woods used in furniture. However, dark woods tend to be more durable, because the same chemicals which provide the coloration may also be part of the tree's defenses against microbial attack. Resins, gums and latexes seal the attackers off from oxygen, while tannins counterattack them.

Trees have preferences as to soil and climate, and what thrives in one place may languish somewhere else. Oak, for example, didn't grow particularly well in the Norwegian forests, whereas Norway was an excellent source of fir. (Tossavainen 1.1)

The woods used in Western Europe during the Middle Ages and the Renaissance included alder (German erle), apple (apfel), ash (esche), beech (buche), birch (birke), boxwood (buchsbaum), cedar (zeder), cherry (kirsche), chestnut (katainien), cornel cherry (kornelkirsche), cranberry schneeball), cypress, ebony (ebenholz), elder (holunder), elm (ulme), fir (tanne), hawthorn (weissdorn), hazel (haselnuss), holly (stechpalme), hornbeam (weissbuche or hainbuche), juniper, larch (larche), laurel (lorbeer), linden (linde), maple (ahorn), oak (eiche), pear (birne), pine (kiefer), plum (pflaume), poplar (pappel), roeswood, rowan (eberesche), service (speierling), spindle (pfaffenhuten), spruce (fichte), sycamore (bergahorn), thorn (schedorn or schawrzdorn), tartary dowood (hartriegel), wanut (walnuss), whitebam, willow (weide), and yew (eibe)(Halstead/Wood). The above list probably omits a few imported luxury woods.

I don't have a chronology of the introduction of forest trees to Germany. However, Nesbet's British forest tree list may be of interest:

Pre-Roman: oak, beech, Scots pine, birch, ash, mountain ash, Scots elm, sallow, aspen, alder, yew, hawthorn.

Introduced by the Romans: plane, chestnut, walnut, English elm, lime (linden), alder, poplar, box, and many ornamental and fruit trees (mulberry, service, hazel, medlar, apple, pear, prune, cherry, peach, apricot, quince and rose) which didn't fully develop .

Before end of fifteenth century (15C): hornbean, sycamore, willow, poplars (white and grey).

16C: spruce, walnut (re-introduced), laburnum, juniper, holly, holm oak, stone or cluster pine, alderberry, viburnum, mulberry.

17C: silver fir, maple, plane (re-introduced), horse-chestnut, larch (1629), robinia, buckthorn.

The trees brought to Britain only in the eighteenth or nineteenth centuries include Weymouth, maritime, cembran and pitch pines, service, cedar, Austrian, yellow and Jeffrey pines, Normann's and Douglas firs, deodar, and eucalyptus.

Down-time Europeans are well aware that there are many new tree species to be found in Africa, Asia and the Americas. However, it was only economical to ship timber by water. Hence, the only tree species likely to make major contributions to the timber trade are those found near the coast, or the banks of navigable rivers.

For the woods of other trees to be exploited, either they must be harvested locally, and their products exported, or the seeds must be transplanted to Europe. Orange trees were brought from India to Europe (protected, if need be, by growing them in orangeries) and re-exported to the Americas. The American Robinia (black locust) was brought to Germany in 1638 (Fernow 62).

Successful transplantation, of course, requires suitable soil and climate conditions, and, even then, it may be many years before the newcomer is mature enough to be commercially exploited. These transfers tend to be either latitudinal (e.g., South America/Africa, or North America/Europe), or between equivalent north/south regions, because the climate has to be the same. New World trees which found homes in the Old World include the Para rubber and cinchona trees. Likewise, the New World was enriched with Old World trees, including coffee, apple and coconut (Robinson).

America's potential as a source of wood and wood products was recognized by Thomas Harriot (1587)(Cox 11). European exploitation of American forests began prior to the RoF. The James River colony began shipping clapboards to England in 1607, and the first American sawmill was built near Richmond in 1611. The Dutch had three sawmills in operation in New Amsterdam as of 1623. New England followed suit soon thereafter; its first sawmills appeared in the early 1630s, one on the Neponset River (Massachusetts) and the other on the Picataqua (New Hampshire). However, lumbering for export was on a small scale until the Dutch War of 1654, which blocked British access to the Baltic. (Cox, 14-15, Cronon, 109-10)

Certain Asian (sappanwood, Caesalpinia sappan, native to India, Malaya and Sri Lanka), Brazilian (brazilwood, Caesalpinia echinata), and Yucatan (logwood, Haemotoxylum campechianum) trees were valued because their heartwoods contained brilliant red dyes. In the 1600s, fifty tons of logwood was worth in excess of 1000 pounds sterling. (Armstrong)

Lignum vitae (gaiac) is highly durable, and has been used in "sheaves for blocks" ((Baker, 226). It was exported by Martinique (settled in 1635) to France in the seventeenth century; 35,000 metric tons were shipped in 1672 (Richards, 433).

Other woods exported to Europe, albeit in small quantities for high-end furniture, included mahogany (used in the Armada ships), rosewood, ebony, teak and sandalwood. (Elliot, 12; Edlin, 218) There was limited trade in ebony beginning in the fourteenth century, rosewood in the fifteenth, and Caribbean mahogany in the sixteenth (Halstead/Trade).

Exotic (or once exotic) trees valued for plant parts other than the wood (e.g., fruit, seed, flowers, leaves, roots) include coffee, cacao (source of chocolate), nutmeg, clove, and various citrus trees.

West Virginia trees include red spruce, hemlock, white oak, yellow poplar, laurel, chestnut oak, walnut, cherry, white pine, persimmon, sassafras, sycamore, hickory, chestnut, locust, maple, beech, basswood, dogwood, and pawpaw. It is uncertain how many of these passed through the Ring of Fire. Of course, those that didn't are still available (if indigenous to America) in the down-time West Virginia!

There are also likely to be some ornamental and fruit trees, of more exotic origin, in Grantville yards and farm plots.

It is interesting to note that both Marion County, West Virginia and modern Thuringia, Germany are in USDA hardiness zone 6 (Plant Hardiness). However, because seventeenth century Thuringia is experiencing the Little Ice Age (albeit not the worst of it), some trees which throve outdoors before the RoF might need to be moved indoors during the winter.

The encyclopedias of Grantville may provide motivation to seek out economically interesting trees in other parts of the world. A few examples follow.

Balsa ( Ochroma pyramidale) is found, scattered, in rainforests in much of Latin America. The tree is ready for cutting at 6-10 years. Balsa is the lightest commercial wood. In the seventeenth century, it was used in native rafts. Centuries later, it was one of the component woods of World War II's "Wooden Wonder." It is the premiere material nowadays for model airplanes.

Redwood ( Sequoia sempervirens) is lightweight and resistant to both fire and decay. It is found on the Pacific Coast of California and Oregon. Seeds of the sequoia were planted in England in 1854. A century later, some of the trees had reached a height of 150 feet. (Baker, 48).

Greenheart ( Chlorocardium rodiei) is noted for its strength (density 61 pounds per cubic foot), and its resistance to marine organisms. It is found in British Guiana. (EB11, "Greenheart").

Teak, because of its strength and durability, is a favored wood for the planking of ships. Indeed, it can be laid as decking over iron plates, since oils in the wood help preserve the iron. Some may question its inclusion in this section, since teak has been used in Asia for over 2,000 years. While there was trade between Europe and the teak-producing areas of Asia (India, Burma, northern Thailand) in the seventeenth century, "the first reference to teak was in the second half of the eighteenth century" (Teak). Kew Gardens didn't obtain its first specimen of Tectona grandis until 1777 (Aiton 57).

Numerous rubber-producing trees are discussed in my article "Bouncing Back" (Grantville Gazette, Volume 6).

Firewood. Regardless of the species of tree, logs which are equal in weight and moisture content have about the same energy content, ranging from 10 megajoules/kilogram for "green" wood to 20 for kiln-dried wood. However, since tree species vary in the density of their wood, they also vary in their heating potential per unit volume.

As populations increased, firewood demand rose, and wood had to be brought in from greater distances. In London, the price of wood in 1600-1650 was in the range of 6-9 grams of silver per million BTUs, up from 4-6 in 1400-1550. Coal, in 1500-1650, sold for 2-4. (Allen 8) Outside London, the price differential was less acute (Unger, 7).

This price differential ultimately encouraged the use of mined coal as a residential heat source, in place of firewood or charcoal. Anthracite coal has a heat content of 26-33 MJ/kg, while that of bituminous coal is 21-30.

Firewood wasn't needed just for residential use. Wood-burners included smiths, bakers, barber-surgeons (who kept bathhouses), brickmakers, glassworkers, saltmakers, cutlers, dyers, potters, founders, and innkeepers (Warde 272, 300-1).

Charcoal. An alternative to burning firewood is to use charcoal. Charcoal may be derived by pyrolyzing wood (heating it in the absence of oxygen, so it chars but doesn't burn). One metric ton of wood yields 150-300 kg charcoal, depending the moisture content of the wood and on kiln efficiency (Keita).

Charcoal's advantage as a fuel is that it "burns hotter and cleaner than wood." (Wikipedia). It has almost three times the energy content of an equal mass of wood. (Logan 127) Consequently, charcoal was the fuel of choice in the iron industry. (Cox, 15) A charcoal fire could achieve the temperature needed to smelt iron (1500 deg. C.). Charcoal is also the "fuel" element of gunpowder (because charcoal burns rapidly).

In 1603, Sir Henry Platt urged that coal could be charred to produce a product ("coke") analogous to wood charcoal. Coke was first used commercially in 1642, for roasting malt. The first use of coke in iron making was in 1709.

Still, even in modern times, some wood is used to make charcoal. Small branches and stems, which might otherwise be wasted, can be used for this purpose. (Edlin, 80)

Fencing. Logan (95) says that in the Middle Ages, fencing was the second most common use of wood (after firemaking). Palisades, used for temporary or outer defenses, were constructed by driving tree trunks vertically into the ground, without gaps, and then binding them together. One could also make anti-cavalry protection by diagonally emplacing stakes, sharpened at both ends, into an earthwork.

Other fences were used merely to restrict the movement of livestock or to establish property lines. The simplest such fence to build was the "zigzag" rail fence ("worm," "snake"). While economical of labor, it was wasteful of wood (Williams 69), and therefore was most popular in North America and perhaps in far northern Europe. The post-and-rail fence was more labor-intensive.

Lumber. Lumber is wood sawn into boards. The lumber, in turn, can be used to construct buildings, ships, furniture and other articles.

Machinery parts—gears, screws, bearings, and so forth—can be made from stout woods such as dogwood (Tree Safari). In the nineteenth century, Peter Mitterdorfer constructed a typewriter almost entirely out of wood! However, the parts will wear out more rapidly than metal ones.

Barrels. Barrels are not just a medium of storage, but also one of transport. A barrel can be rolled.

Log cabins. While the standard English and Dutch construction was sparing in its use of wood, that wasn't true in the more forested parts of Europe, including southern Germany, Sweden and Finland. Immigrants from those regions were the first to construct log cabins in America, from 1638 on. (Lillard, 15).

Saps. Saps are plant fluids. In the seventeenth century, the Europeans collected a type of sap (pine resin) from pine trees. The raw resin was separated by distillation into volatile liquid (turpentine) and non-volatile solid (rosin, pine tar, pitch) components. Turpentine was used medically, or as a solvent in paint, while pine tar was used as a waterproofing agent, especially on ships. Resins were also used directly as coatings and adhesives. Tar and turpentine were considered strategic materials, "naval stores."

The British sought to develop a domestic naval stores industry in the American colonies, to reduce their dependency on the Baltic trade. However, through ignorance, there was much waste. Trees were felled which were unsuitable for pitch production, and trees were tapped for turpentine in a manner which caused them to die prematurely. (Cox, 17)

Wood ash. Burning beech trees (and certain other hardwoods) results in an ash rich in potash (potassium carbonate). Potash is used as a flux in glassmaking (see Cooper, "In Vitro Veritas," GG5). As an alkali, it can also be mixed with fat to make soap.

At least in America, the production methods were crude, the final product being less than 25% potassium carbonate. "Three to five acres of timber had to be burnt to yield a ton of potash." (Cox, 16). Pearlash is 3-5 times more concentrated (Williams, 74).

Wood ashes, being sources of calcium, potassium, magnesium and (to a lesser extent) sodium, can also be used as fertilizer, or to neutralize acid soils. Unfortunately, they don't provide nitrogen, because that element is lost in the burning process.

Cork. Cork lies just beneath the bark of the cork oak (Quercus suber), which grows in Portugal, Spain, France, Italy and on the Barbary Coast. Its best known use, of course, is in stopping wine bottles. Cork's key advantage is that it is impermeable to gas and liquids, thanks to the presence of the wax suberin. Cork is also used in life preservers and buoys. Cork can be harvested once the tree is at least 25 years old, and thereafter every decade or so.

Tannins. Animal hides can be tanned (converted into leather) by soaking them in solutions rich in tannins. The tannins are extracted from the bark, or other parts, of certain trees, such as the oak and sweet chestnut in the Northern Hemisphere, and the quebracho tree and various Acacias in the South.

Inks and dyes were made from the tannin-rich galls of various oaks. (Logan 189).

Drugs. In 1535, Jacques Cartier's expedition halted a scurvy outbreak by use of an Indian remedy, an infusion prepared from the bark and leaves of the "Annedda" tree. Scholars are not entirely sure which tree this was; the best candidates are (in decreasing order of probability) the Eastern white cedar ( Thuja occidentalis), the white spruce ( Picea glauca), the black spruce ( Picea mariana), the Eastern White Pine ( Tsuga canadensis), and the Balsam Fir ( Abies balsamea) In the late eighteenth century, the British Admiralty advised that "Spruce Beer" be given to not-yet-Limey sailors. (Houston; Lillard 28-29). Quinine, an anti-malarial agent, is extracted from the bark of the Cinchona trees of the Andes.

Spices. A number of spices, including cloves (from Eugenia caryophillus) and cinnamon (from Cinnamomum zeylanicum), are produced by trees.

Oils. The nuts of oil palms, native to West Africa ( Elaeis guineensis) and tropical America ( Elaseis oleifera), produce an edible oil. The nuts of wild trees have been harvested and traded since ancient Egyptian times, and were used by the European slave trade to feed their human cargoes. It was later used by British factories as a lubricant, and this in turn led to the establishment of plantations in southeast Asia as well as in Africa.

The oils of other trees found other uses, e.g., sandalwood oil as a pharmaceutical and a perfume.

Firewood. A recurring problem with firewood estimates is failure to specify whether the volume is of solid wood or stacked lumber; for the latter, 25-50% is air. Halstead says the average annual per capita use of firewood in early modern Europe was 3-4 cubic meters (m3). Warde (265-6) says that in Wurttemberg, a "household" (mean size probably 4.25) needed 3.4-10 m3 of stacked lumber. That implies perhaps 1.2 m3solid wood /person. (Estimates of late 18th century annual consumption ranged from 0.4-3.9.) In 1760s America, consumption was about 22 m3/person (Williams 81, 78).

Shipbuilding. Timber was needed for the masts (pine and spruce), frames (oak), and planks (cedar, pine, oak) of sailing ships. Something like 3,000-4,000 "loads" (each fifty cubic feet of wood, the product of a single large tree) were needed for a Napoleonic 74-gunner. (Wood 14, Cordingly 19) Vast quantities of timber were needed for just the frames of naval vessels: 34,000 cubic feet for a ship of the line, 23,000 for a first class frigate, 8,000 for a sloop, and 1,800 for a schooner. (Wood, 55)

It was also important to find the right kind of tree for a particular use. For example, for the masts, the builders wanted tall (perhaps 120 feet), straight trees, which were ever more difficult to find in European forests. The American mast trees had to be transported in special cargo ships, with ports in the stern. (Pike, 49).

Oak, because of its strength and resistance to rot, was the preferred hull wood. Each part of the hull had a certain desired shape, and the trees were chosen to suit (Wood 8). Thus, forest oaks were used for the sternposts and planking, which needed to be straight, while isolated trees, with greater branching, provided the curved "compass timber." (Cordingly 19-20).

Buildings. "Each new [medieval] house required 12-16 oak logs and a new church might require the wood from 300-400 trees." (Halstead/Trade) Thirty oaks were allowed for a new building in Lippe, Germany, in 1600 (Warde 276). Clark says that around 1700, the average Englishman consumed almost five cubic feet of construction timber.

In Wurttemberg, ducal ordinances encouraged the use of stone for the first floor. (Warde, 274).

The influx of displaced Germans into the vicinity of Grantville caused a building boom, and the "massive amount of wood construction going up" led car dealer Keith Trumble to become a nail manufacturer. ( 1632, Chap. 43).

Charcoal iron. Williams (106), for eighteenth century America, estimates 10-30 cords wood/acre cleared; 20-40 bushels of charcoal [bushel ~20 pounds] per cord [cord=4800-6000 pounds] burnt; 125-400 bushels charcoal per ton pig iron produced. (Cp. Logan 127; Clark)

An internet discussion of late nineteenth century practice says 30-100 cords wood/acre; 40-50 bushels charcoal/cord, 128 bushels charcoal/ton iron. A single pit might process fifty cords in 7-10 days. (Europa)

Potash manufacture. "Three to five acres of timber had to be burnt to yield a ton of potash." (Cox, 16). Halstead says that a glassworks used the equivalent of 80 hectares (198 acres) of forest in a year. Warde (300) reports that producing one kilogram of glass required 1-3 cubic meters of wood (both as a source of potash and as fuel).

Pitch, tar and turpentine. Two thousand pine trees produced about five barrels resin a day. The resin was distilled; the distillate was turpentine, the residue, tar. ( A cord, 3.62 m3, of wood yielded 40-50 gallons tar.) Removing more volatiles from the tar by a further distillation yielded pitch, which cost twice as much (Williams 84-88).

The price of wood is very much dependent on transport costs. Warde (312) says that "the hospital of Markgroningen bought wood from the rafters at Bissingen for around 3 fl. per fathom [3.3 cubic meters] in the late 1590s, wood that could be purchased for as little as 0.07-0.14 fl. upriver in the Black Forest. . . ."

In Amsterdam in the 1640s, 100 pounds of "Sappan Wood" (a Philippine dye wood) could be purchased for 11-18 guilders. In 1632-35, the price of "Yellow Wood" ( Podocarpus latifolius?) was 4-6 guilders, whereas Pernambuco Wood was 43-45. (Posthumus)

Potash is made from wood. In 1632-35, the best Danzig potash cost 13.2-20.25 guilders per 100 pounds.

In railroading. Early locomotives were wood burners, and we are talking about a lot of wood; say, 140 cords per track mile per year. The "iron horses" pulled rolling stock which, in the nineteenth century, were primarily made of wood. While they steamed along steel rails, those rails were supported by wooden ties. American railroads used 39,000,000 cross-ties in 1870 alone. Wood was also used to construct bridges and stations. (Cox 100, 113). For more information on wood-burning by locomotives, see my "Saddling the Iron Horse" (GG7) and the "Locomotive Addendum" posted to www.1632.org .

Corduroy and plank roads. While there was limited pre-RoF use of wood in constructing roads over swamplands, the heyday of the wooden road, the "Farmer's Railroad," was in the nineteenth century. Corduroy roads used whole or split logs; plank roads, obviously, used planks and gave a smoother ride. The wooden roads appeared first in Russia, then in Canada, and finally in the United States. A fuller discussion appears in my article "All Roads Lead to Magdeburg: Roadbuilding in 1632" ( Grantville Gazette, Volume Seven).

Aircraft. Wood has high strength and stiffness in proportion to its weight, which is a very good thing if you are trying to build an aircraft. This is particularly true for the "aircraft woods," such as Sitka spruce, Douglas fir, Noble fir, canary whitewood, kara redwood, white pine, western hemlock, and birch. (Desch 148). Balsa, the "lightest" commercial wood, is used primarily in models. However it has been used in full-scale aircraft. Since it's soft, it's ideally sandwiched in-between hardwoods. (Lienhard)

The biggest problem with wooden aircraft is rot. Not just of the wood itself, but also of the glues used.

Toothpicks. Pike (32) says that the toothpick was, "next to the spittoon, . . . the greatest social invention of the [nineteenth] century."

Telegraph and Telephone Poles. Telegraph companies erected 300,000 poles in 1882. (Lillard 147).

"Balloon Frame" and "Platform Frame" Houses. Houses can be built using just light, dimensional lumber, nailed together. These "balloon frame" houses were popular in nineteenth century America, once machine-made nails were available, since the houses could be assembled cheaply and quickly, without the assistance of carpenters. No dovetailed joints, no mortise and tenon. (Cox, 72-3)

In the late twentieth century, the predominant light form construction system is platform framing. This, too uses dimensional lumber. However, in balloon framing, the uprights (studs) run all the way from the base of the first floor to the top of the highest floor. In contrast, in platform framing, the uprights are one floor tall; that is, each floor is built on the platform formed by the floor beneath it.

The framing can be strengthened either by diagonal braces or by panels.

Let me begin with a caveat: some of the products mentioned here, such as latex and maple sap, are new to the Europeans, but not to native peoples.

Paper. During the seventeenth century, paper was made from fiber crops, such as cotton and flax (linen). Wood wasn't pulped to make paper until the nineteenth century, and this substantially reduced the cost of paper (and hence of books).

Wood can be pulped by purely mechanical means, or alternatively the wood is chipped and then digested chemically (with sulfite, caustic soda, or sulfate). It took one cord of pulpwood to make one ton of pulp. (Pike 269).

Activated charcoal. The highly porous form of charcoal known as "activated charcoal" is able to absorb gases and liquids, and therefore has been used in water purification plants, gas mask filters, and in the emergency treatment of certain poisons.

Plywood. Plywood (a re-invention; legionairies carried plywood shields) is the result of gluing together three or more thin sheets of wood, cris-crossing the direction of the grain. The wood sheets can come from different trees; the plywood of the De Havilland Mosquito combined balsa and birch.

For maximum strength, the glue should be applied so it penetrates deeply into the lumens of the wood. In general, that means the wood must be sanded, preferably mechanically.

The choice of glue is also important. Hide glue (which is gelatine based) is water-sensitive, and also attacked by bacteria and fungi. Casein glue is moisture resistant, but still subject to rot. Nonetheless, it was the glue of choice in the aircraft of the Thirties. Synthetic resin glues, such as phenol-formaledehyde, urea-formaldehyde, resorcinol formaldehyde, and epoxy, will eventually be available in the 1632 Universe.

Fiberboard and Particle Board. In fiberboard, wood is separated into fibers, which are rejoined with a resin. In particle board, wood particles (sawdust, wood shavings or wood chips) are glued together to make a composite wood.

Sawdust or "wood wool" (loose wood fibers) have been incorporated into cement to form composites, usually to form panels. (Farmer, 58). The cement serves, like a resin or glue, as the binding agent.

Wood pyrolysis products. When wood is pyrolyzed to make charcoal, a number of other chemicals are produced. These include acetic acid, methyl alchohol ("wood alcohol"), and acetone.

Cellulosic polymers. The wood pulp can be used in the production of rayon, cellophane, cellulose acetate, cellulose butyrate, carboxymethylcellulose, and so forth.

Latex and Rubber. Certain trees can be tapped to collect latex, a milky sap. The latex of the Brazilian rubber tree, Hevea brasiliensis, can be used as is (e.g., disposable gloves) or coagulated to make rubber. Other latex products include chicle (from Manikara chicle), balata (from Manikara bidentata), and gutta percha (from Palaquium gutta).

Maple syrup. The American Indians were quite familiar with tree sugar. By the mid-1600s, the sweet (2-6% sugar) sap of the sugar maple (Acer saccharum) was bartered to European settlers by Indians of the Great Lakes and St. Lawrence River regions. The sugar maple tree can be tapped once it is forty years old, and a single tree will produce 10-70 gallons of sap each year. It takes over forty gallons of sap to make one gallon of maple syrup. (GSFC )

Forests have uses other than as a source of products. At least one of them is well known to the down-timers; they provide cover for animals. Others are mentioned in the 1911 Encyclopedia Britannica (EB11). They moderate the climate, help prevent soil erosion and consequent flooding, and act as windbreaks which protect crops from storm damage. (see also Baker, 74-5). Chances are that the down-timers are aware of these utilities, too. However, they don't have a clearly articulated concept of trees as nodes in an ecological web.

A forest does you no good, as a source of timber, if you can't economically transport the logs to where the wood is needed. In the seventeenth century, the only economical long-distance shipping method was by water. Even "in [late eighteenth century] England it was reckoned that any tree more than 40 miles from water transport was of no use for the navy," and in France there then were legal restrictions on private felling of oak trees within fifteen leagues of the sea or six leagues of any navigable river (Cordingly 19). Shipping coal, another bulk commodity, by water (down the Tyne and up the Thames to London) caused the price of Newcastle coal to increase 6-9 fold (Unger 8-9, Allen 8).

Unger's response to historians who said that there was a timber or energy crisis in early modern Europe was that a large part of the delivered cost of wood (or coal) was its transport cost, and hence it would be more apt to speak of a "transport crisis."

Short-haul transportation. Logs can be dragged (hauled while lying on the ground; "snaked"), skidded (hauled with one end up), or carried (both ends up) to a collection point of some kind. For dragging or skidding, they are attached to a chain or cable which is pulled by animals (oxen, horses or mules), a vehicle (steam or gasoline powered), or a stationary engine. The logs can be carried on an animal-pulled sled (on snow) or logging cart (a cart with a single pair of very large diameter wheels)(Wood , 111-18), on a logging truck, or even on an aerial cable (skyline)(Raphael 138-43). Or they can be floated, on a stream or even a log flume. There is even the possibility of ballooning or helicoptering logs from the woods to the collection point. (Pike 271; Raphael 143-54)

Clarkson Fig. 217 shows the details of a skidding harness, and Fig. 226, the arrangement of an aerial cable for skidding logs.

In the seventeenth century, short-haul transportation was limited to animal and water power. The likely uptime innovations will involve the use of enginery and perhaps also the aerial cable. (Brown 125, 190).

An example of a nineteenth-century machine is the Lombard steam log-hauler. It looked like an ordinary locomotive except that it had crawler treads. It could haul a couple of hundred tons at a speed of 4-5 mph. (Pike, 170-4; Patten). It ultimately was replaced by gasoline-powered tractors.

We turn now to long-haul transport methods, using roads, railroads and rivers.

Logging Railroads. While logging railroads occasionally used animal power, locomotives were preferred. (Brown 329) The issue of logging locomotives was touched upon in Carsten Edelberger's "Railroading in 1632" and my "Saddling the Iron Horse" (both Grantville Gazette, Volume 7). In essence, because logging railroads were temporary, and had to cope with sharp curves and steep grades, it was advantageous to use geared locomotives (Shay, Climax, Heisler, Baldwin, Dunkirk) instead of the conventional rod type.

Clarkson provides a lot of information about logging locomotives. For example, he gives these specifications for the Northeast Lumber Company's Shay No. 3 engine: running on 36" track, driving wheel diameter 39", three cylinders (diameter 10", stroke 10"), boiler (39 3/8" diameter, 180 p.s.i.), firebox (54 3/4" long and 38 5/8" wide), wheelbase (truck 4'2", engine 26'5"), 104 tubes (2" diameter, 8'11" long), grate area 14.7 square feet, heating surface (482 square feet in tubes, 67 in firebox), wheelbase (4'2" truck, 26'5" engine), factor of adhesion 4.55, weight 80,300 pounds, maximum tractive power 17,660 pounds, water capacity 1200 gallons, fuel capacity 1.75 tons soft coal. (Fig. 111; see also Figs. 112, 128, and pp. 55-61.

The rails themselves could also be unconventional. On occasion, they were wood (e.g., peeled spruce logs) instead of iron or steel. (Pike 162-3, Brown 322, 329). If so, the wheels of the engine and log trucks were likely to be double-flanged, so they could hold on better. (Clarkson, 57).

Portable plank roads. These can be used for short distances, and are most useful in marshy areas. (Brown 323).

River drives. This refers to simply floating the logs downstream. This clearly is most suitable if the wood has good floatability. Such woods include spruce, white pine, Norway pine, yellow poplar, aspen and willow. On the other hand, oak, birch, elm and ash are all of a density unsuitable for river driving. (Brown 348-9).

Log driving was practiced in the seventeenth century, at least in Sweden ("Klaralven," Wikipedia). And the down-timers are familiar with the trick of holding water back in splash dams, and then releasing it all at once, so that boats can navigate a relatively shallow stream. The same can be done with logs. However, there were some interesting later innovations.

For example, in nineteenth-century America, booms were used both to store logs upriver and capture them downriver, but there were frequent legal disputes with other river users . Clarkson describes the flexible pocket boom and the crib boom (53). Levi Pond invented the sheer (fin) boom in 1862; it had a moveable fin hinged to a fixed boom. The presence of the fin meant that the boom could be opened to allow river traffic to pass. (Cox, 84-5, 121).

In America, rafting was more popular than log driving until the early nineteenth century, possibly because of the logistical problems of sorting out the logs and paying for the drive (Williams, 98-99).

River rafts and barges. Wood which can't float well can be carried downstream on rafts or barges. If the current is slow, these can be towed by animals on towpaths. The principal up-time improvement would be to replace the animal teams with machinery, most likely a steam-powered tug. Rafts, of course, were disassembled and sawn. Indeed, even barges didn't have to be returned upstream; flimsily constructed "arks" took a one-way trip to the sawmill.

Clarkson (48-9) says that an average American log raft could carry about 70 logs (25,000 board feet). Clarkson describes how the logs were fastened together, and how the rafts were steered.

Rafts and barges couldn't be used on the smallest waterways. So if the wood couldn't float, and wasn't near a large enough stream, it would have to be transported overland or left standing.

After 1691, Rhinelanders made use of giant log rafts—up to 320 meters long, 50 meters wide, 2.2 meters thick, each comprising up to 28,000 cubic meters of wood. A single raft might have a crew of over 500 men. Obviously, you needed a wide, clear waterway to ship this way. (De Vries, 424).

Ocean rafts. The rafting of timbers from America to England was first proposed in the eighteenth century. However, it was easier said than done; both storms and teredos were troublesome. There has been more success with rafting logs along the Pacific Coast of North America. (Brown, 382-6).

Transport costs can be reduced by peeling off bark (Pike 263), or sawing the logs near the point of origin (it is cheaper to ship timber)(Halstead), or by seasoning the wood (reducing its moisture content) before shipping (Gordon?).

The purpose of transport methods is to get the timber to the sawmill. The alternative is to bring the sawmill to the timber. Portable sawmills have existed since the Seventies; they are used mostly for 'salvage logging', that is, recovering logs left behind by earlier loggers. (Raphael 154-6)

Ax. Robert Pike says that it was the ax which conquered the American wilderness. During the eighteenth and nineteenth centuries, the European ax was modified to make it more suitable for American wilderness life. According to EA, "Ax," the blade was made thinner, broader, and sharper, and the handle was set forward in the blade." The preferred handle wood was hickory. As to the ax head, this was ultimately made of steel. (Lillard, 20-21; Cox 64; Pike 15-9)

Ideally, the handle was inserted into the ax head (hung) at just the right angle to suit its user. Even when machine-made handles became available (1853), they were sold separately from the ax heads, so the customer could hang his ax.

The curved ax handle was an American innovation, which reduced the shock of the stroke.

The ax evolved into several specialised forms: the single-bitted pole-axe, the double-bitted axe, and the broad ax. (Pike, 15-20).

The Peavey. You've seen this if you ever seen a movie in which lumberjacks were trying to break up a logjam. It's a staff with a spike at one end and a side hook on the other. It was invented in 1858. (Lillard, 151, Cox 131; Pike 106)

Chain Saw. In the twentieth century, the powered chain saw replaced hand tools as the preferred means for felling and bucking (sectioning) trees. With a power saw, one man can cut twice as much wood.

There are certainly a number of chain saws in Grantville. However, there are a lot more trunks in Thuringia than there are chain saws! So the existing ones will be most useful, in the long run, as models for would-be reconstructors.

Sawmills. Before there were sawmills, wood was sawn in a pit by a two man team. They used a long saw with two handles. A grating was placed over the saw pit, and the "top sawyer" stood atop it, and pulled the saw up. The other, the "pitman", was underneath the grating, and pulled the saw down. (Pike 39). Pit saw productivity was 100-200 board feet per day. (Williams, 96, 247; Clarkson 14)

The first reference to a sawmill is from 1204 (Halstead). Sawmills replaced human power with animal, water, wind and, ultimately, steam power. Animal power had the disadvantage that the animals had to be fed. Water power was available only in certain locations (near streams which provided a sufficient "head" to turn the water wheel), and was subject to interruption by droughts, floods, and freezes.

Wind power, harnessed by windmills, could only be used where there were steady winds. The first wind-powered sawmill was patented and built by Cornelis Corneliszoon in the 1590s. ("Sawmill," Wikipedia).

In America, at least, communities strongly encouraged sawmill construction. "[T]owns made grants to and townsfolk held share in what was ... a cooperative enterprise." The grants were of the privilege of using a particular river site, and sometimes also of cash, land, or lumber. In 1650-99 New York, two sawmills were constructed before settlement of the site in question, three within only 5-9 years after (Williams 94-5).

Sawmills were improved, over the last few centuries, in two major aspects. First, with respect to the motive power. Steam engines were first used to drive American sawmills in 1803, and the typical 1838 engine was twenty horsepower. That was still five to ten times as powerful as the water wheel, and more dependable to boot. At least when it didn't explode. (Cox 67-8). Steam engines, burning wood or coal, could be located anywhere.

That didn't mean that water power became completely obsolete. Even in the twentieth century, there are water-powered mills. However, the old wooden wheel has been replaced with one made of iron. (Pike 178-9)

Another major area of improvement was in the saw design (Pike, 175-82). In a sawmill, the saw is held stationary, and the log is moved against it. A reciprocating sash saw moves back and forth across the log. A circular saw has its teeth on the edge of a disk, and it cuts as it spins about its axis. A band saw has a flexible blade which rides, belt-like, around two wheels.

There are several considerations in choosing a sawing mechanism. These include speed, durability, log size capacity, and the size of the kerf. The kerf of a saw is the width of the saw cut. This is usually wider than the saw blade itself because the teeth are usually formed so that they curve, alternately, to one side or the other. This helps prevent the blade from binding (getting caught in the wood). The greater the kerf, the more wood is wasted as sawdust.

The sash saw is the only kind seen in down-time sawmills. A sawmill using a water-powered sash saw could produce 500-3,000 board feet a day. The speed was of course dependent on the rapidity of the reciprocation; even early nineteenth century mills achieved fewer than eighty strokes per minute. Somewhat unfairly, they received the nickname "up today and down tomorrow" saws. (Clarkson 16; Williams 96, 247)

The earliest improvements retained the reciprocating action. First of all, several blades could be ganged together (connected to a single frame driven by the water wheel) so that a log could be completely cut in a single pass. Secondly, the heavy frame of the sash saw could be dispensed if the saw was made a bit thicker, resulting in a "muley saw." Being lighter, it could move faster, doubling the output (Cox, 66).

The circular saw (buzz saw) was invented in the late eighteenth century, but wasn't used in sawmills until the nineteenth century. Its great advantage was speed; the sash and muley saws only cut on one stroke, while the circular saw's cutting action was continuous. However, it could only saw a log whose diameter was less than half that of the saw itself. The size of the saw, in turn, was limited by the quality of the metal. Early circular saws also had a tendency to wobble, and hence a very large kerf. They also tended to overheat, warp and jam. (Clarkson 19-22; Pike 179, Cox 66-7)

The log diameter problem was ameliorated by the use of two circular saws, one above and the other below the log. (Pursell 157) And the kerf was somewhat reduced when suitable steels became available. But the circular saw nonetheless was clearly not a final solution.

The band saw became practical in the late nineteenth century, when metallurgy had advanced sufficiently that the long, flexible blade could survive the rigors of sawing. The band saw's first advantage over the circular saw was its narrow blade (and hence narrow kerf). In a nineteenth century American sawmill, about 31% of the wood cut with a circular saw was converted into sawdust. A contemporary band saw would have wasted only 8%. (Hawke, Nuts and Bolts of the Past, 204-5; Cox 41, 66). The second advantage of the band saw was that it could cut even the thickest logs.

Like the circular saw, the band saw was fast. Steam powered circular or band saws of the late nineteenth century could produce over 100,000 board feet per day. (Pursell 157). The world record is 221,319 board feet (714 logs) sawed, with a band saw, in eleven hours (Pike 180).There is a "Band saw" article in Encyclopedia Americana, and it gives recommendations as to the thickness of the blade, and its speed of movement. Unfortunately, it doesn't provide any metallurgical specifications. The band sawmills of West Virginia are also described by Clarkson (23-33), which is in the Grantville (Mannington) Public Library. So far as the saw is concerned, it just says, "high grade steel."

After the band saw became the principal sawing mechanism, circular saws remained useful for edging work. (Pike 175).

Besides the saw itself, and the motive power, one must also consider how the log is delivered to the saw. This was originally done by hand. Later, a mechanical device was used to turn logs over as needed. Also, steam power was used to drive "live" rollers, which in turn drove the logs onward. (Pike 179)

Planing Machinery. In 1632, planing (the smoothing of the surface of the lumber) was done by hand. Planing machinery was developed in the nineteenth century.

Stoves and Fireplaces. Even in the mid-twentieth century, over 50% of world wood consumption was for fuel. If wood must be burnt, it is better that it be burnt efficiently. Some American fireplaces used ten to fifteen cords of firewood annually, but wasted four-fifths of the heat generated. (Cox 62) Desch (183-4) says that open fires, and primitive stove and ovens, waste over 90% of the fuel value of the wood. Benjamin Franklin's stove (1714) was specifically intended to conserve wood. (Cox 63)

Accelerated Seasoning. Wood will warp if its moisture content is too high, relative to ambient conditions. Seasoning dries out the wood. However, if the drying is too rapid, the outside of the wood will shrink so much faster than the inside that the wood will split.

In the seventeenth century, wood was seasoned by leaving it out in the air. (Sometimes trees were killed by girdling, but not cut down, so that the wood seasoned in the dead trunk.) The thicker the timbers, the longer it took; as much as seven years to season the "hearts of oak" for a sailing ship. Shipyards had to keep "large stocks of valuable timber seasoned and seasoning."

EB11/Timber says that one can place the timber in "well-ventilated rooms kept at a temperature of from 80° to 150° F," reducing the seasoning time to one-tenth of that required for natural seasoning. It also mentions a pretreatment in which water is used to force out sap.

According to Gordon (144), "by carefully controlling the drying rates in large kilns the time for seasoning can be reduced to a matter of days or weeks."

Moreover, the use of laminated woods (see plywoods, above) reduces seasoning time. The thinner the wood, the faster it can be seasoned (the moisture gradient in the wood isn't as steep).

Preservatives. Wood is subject to attack by fungi and various invertebrates (insects, marine borers), Tar (itself a wood product) has been used as a preservative since ancient times. Another early preservative, creosote, was originally a wood tar derivative, but was later made from coal tar.

Modern wood preservatives can extend the life of lumber by five to ten fold. One group of preservatives are copper salts, which include copper naphthenate, alkaline copper quarternary (ACQ), chromated copper arsenate (CCA), copper azole (CA), and ammoniacal copper zinc arsenate (ASCA). Unfortunately they are all toxic to humans. That is also true of pentachlorophenol. One non-toxic alternative is borate, but borate can be washed out of the wood and so it unsuitable for outdoor use.

Preservatives can be applied by non-pressure methods such as brushing, spraying, dipping or steeping. Pressure processes can achieve a deeper penetration, but require a greater investment in equipment.

Fire retardants. Wood-eating lifeforms aren't the only danger wood faces; fire is another. Wood can be impregnated with fire retardant. (EA).

The development of the coal industry will reduce the demand for wood (and wood charcoal) as a fuel, while steel smelters and concrete mixers will partially replace wood construction in ships and buildings, respectively.

Potassium carbonate can be made by electrolyzing potassium chloride in water, producing potassium hydroxide, and then carbonating with carbon dioxide. This process will ultimately doom the "potash" industry.

Barbed wire fences are a substitute for wood fences, and allow the co-existence of farmers and cattle ranchers.

Better transportation networks (asphalt roads, and railroads) will make it easier to log timber in areas which were previously considered inaccessible, and will also reduce the costs of shipping timber and lumber to communities remote from both the coast and navigable rivers. Water transportation will also be improved by the introduction of steamships.

Steam and electricity will make it possible for trees to be hewn and sawn much more rapidly than before.

Improvements in medicine and sanitation will result in population growth, and thus in increased demand for all products.

The modern agroscientist defines a forest as an "area of land on which forest trees are the dominant vegetation." A "tree,", in turn, is a "woody plant ten or more feet high at maturity," while a "forest tree" is one which normally grow so close to other trees "that their crowns do not have room to expand to their full width... and [which] lose their lower branches. . . ." (Chapman 3). Lay folk think of a forest as a large area which is heavily wooded.

The word "foresta" first appears in the laws of the Lombards, where it referred to woods which had been placed off limits (Latin forestare, to exclude) to all save the king and his favorites. The purpose of this "afforestation" was to protect game so it was preserved for the royal hunt. The forest wasn't necessarily densely wooded; it merely needed to be land which supported suitable wildlife (especially deer) and marked as under royal protection.

Under English forest law, which was established by William the Conqueror, one class of offenses was that of trespass against the vert (vegetation). These crimes included felling trees, especially if the land was entirely cleared (assarted) for farming; fencing off any part of the land (purpresture), or erecting buildings upon it. Forest law was moderated (for a price) by granting the right to take firewood (estover), or to pasture animals (pannage; agistment). (Harrison, 69-75; Wikipedia).

As in England, in the medieval period, forest management in Germany was primarily limited to the protection of the hunting rights of the nobility. (Fernow 35) When Grantville arrived in Thuringia, most of the forest land was owned by the aristocracy, and a license was needed to hunt there. A law blissfully ignored by the up-timers. ( 1632, Chap. 43).

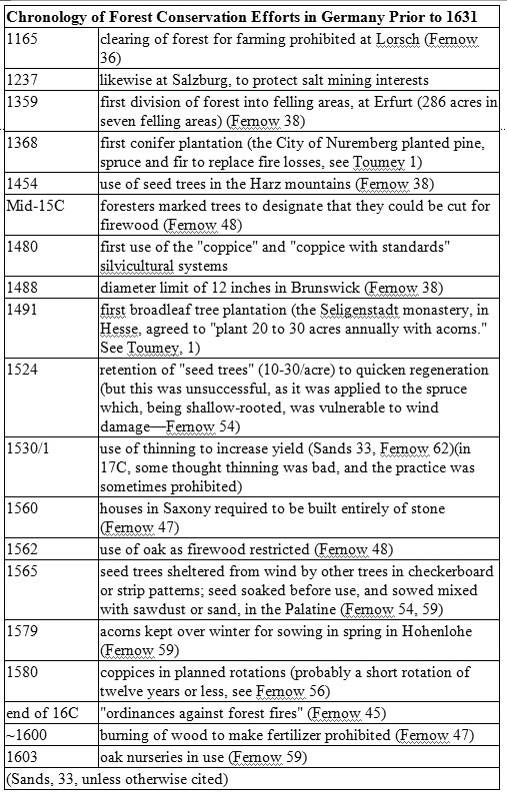

Beginning in the twelfth century, we can find local ordinances which limited deforestation, and in the late fourteenth century, the first efforts at actively promoting reforestation.

There were also ordinances which prohibited pasturing in recently logged areas (as the animals would eat the sprouts and thus hinder reforestation), required preservation of certain trees (e.g., oak, beech, larch or pine), allowed only the use of dry wood as fuel, prohibited or restricted the sale of wood to foreigners.

The 1598 Brunswick forest law said that "every farmer shall every year at the proper time set out ten young oaks, every half farmer five, every farm laborer three, well taken up with roots (wildlings), and plant them in the commons or openings at Martini (November) or Mitfasten (Easter) and cover them with thorn brush." (Fernow 58)

In the early seventeenth century, the Finns cleared land for farming by burning the timber. When Sweden, with the aid of the Dutch industrialist Louis de Geer, sought to mine and smelt copper, it prohibited such waste—the wood was needed as fuel for the smelter. Finnish scofflaws were forced to migrate to New Sweden, the colony founded in Delaware in 1637. (Voyages of David de Vries, 133).

Even without up-timer intervention, comprehensive forestry management was an idea whose time had almost come in the 1630s. John Evelyn wrote Silva: or a Discourse of Forest Trees, and the Propagation of Timber in 1664, and Colbert, minister to Louis XIV, persuaded the Sun King to sign off on the French Forest Ordinance of 1669. Forest management began in Russia under Tsar Aleksei Mikhailovitch; 67 of the articles in the 1649 Council Code regulated the use of forests. (Teplyakov 2)

Enforcement of forestry laws is notoriously difficult. (Lillard, 122-32; Cox, 25, 30, 99-100, 139-42, 177-9; Pike 44-51; Wood 18, 58-9, 62) The forest lands are difficult to traverse, and the thicker the stands, the shorter the range of visibility. If sufficient foresters are deployed to police the woods, then there are that many more individuals who can be bribed to overlook tree poaching.

Warde's Ecology, Economy and State Formation in Early Modern Germany has a detailed analysis of the forest district ( Forstamt) of Leonberg in the sixteenth and seventeenth centuries. I hope it is reasonably representative of conditions elsewhere in central Europe.

Forstamt Leonberg was part of the Duchy of Wurttemberg, and was bordered on the west by the Black Forest. The Forstamt was one-third wooded in the west, and only one-fifth in the east. (Warde 52). It contained five small towns and fifty-three villages, and ran up to the walls of Stuttgart. (43). I don't know what fraction of the Duchy it occupied. The arboreal riches of the Forstamt included oak, birch, beech, hazel, alder, aspen, Scots pine, silver fir, ash, hornbeam, willow, and fruit trees (apple and pear)(231-5). The yield of stacked wood in 1713 was 1.6-5.4 cubic meters/hectare (248).

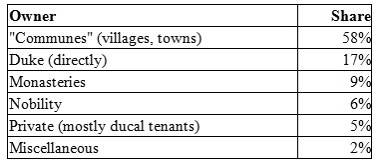

Warde provides this breakdown of forest ownership in 1682:

(3% unaccounted for) (106-7)

Warde's "communal" forests are best thought of as owned by a corporate-like legal entity, the "mark association," which in Wurttemberg corresponded to a village or town, but elsewhere in Germany (perhaps in a mountain valley) could be a looser association of dispersed farms (Huebner, Vol. I, Sec. 17).

Ducal forests (2300 hectares in 1682; 257) were organized into forest districts ( Forstamter) administered by a forester. The foresters of Leonberg included members of the minor nobility (Gall von Sachsenheim; Friedrich Jacob von Reischach), but more often were professional foresters who had held similar positions in connection with lesser woodlands (Ulrich Bauder, 1589-1613?, Hans Ulrich Bauder, 1613?-1648?).

Forester pay was a pittance in cash, together with free use of a house, clothing, and various payments in kind. The latter exceeded what the forester would use himself, and the excess could be traded or sold to others, depending on the acumen of the forester. (Warde 185). Foresters also had some kind of expense account; they filed claims for food and lodging when away from the town of Leonberg. In the fiscal year 1585-6, Philip Rossach filed 186 claims. Ulrich Bauder had 129 in 1609-10. (188-9).

Figure that a forester might spend one-third of his time facilitating ducal hunts (locating "trophy" stags, getting hunting dogs in place, and chasing poachers), one-third dealing directly with the wood (surveying, and overseeing the cutting and transport of the timber), and one-third on miscellaneous administrative tasks (riding the bounds, supervising subordinates, attending court, preparing reports, etc.)(189)

Each forstamt was further divided into wards, and each ward (Hut) was monitored by a forest warden (Forstknechten. There were thirteen wardens in 1585 (186). The precise size of a ward isn't mentioned, but Warde says that by 1523, wardens were "within a day's walk of all of the district."

We don't know too much about the specific duties of the wardens, but it is safe to assume that they carried out the "detail work" for the forester. The forester might lead a group of wardens against a gang of poachers, but the less exciting work of the ward (e.g., counting the number of stags in June and of wild boar in October) was probably done individually.

Wardens tended to be chosen from the locality, which meant that they had a good knowledge of their ward. It also meant that they could have overly cozy relationships with the farmers and townsmen that they sometimes had to guard the forest against. The corruption of the wardens wasn't surprising, because the pay was poor. In the tax returns of 1544-5, none had an assessment over 160 florins. (The mean for the 4,000 inhabitants of Amt Leonberg was 246, Warde 124.)

The ducal forest income came both from the sale of wood, and of privileges, e.g., gathering acorns, or hunting rights (215). Forest income was usually 8-10% of the total ducal income, but in 1629-31, it reached 14% (216). In 1600, firewood was about 90% of the wood sold from ducal woodlands (264). Beyond that (I think), in 1604-5, ducal woodlands sold 163 trees (export?), and another 137 oaks and 203 firs were put to use within the duchy (e.g., repairing millworks)(254-5).

The ducal foresters and wardens concerned themselves with the non-ducal woodlands only if the latter were grossly mismanaged (191).

The communal administrative system could be complex. First, there were the "ordained in the wood" ( Verordnete im Wald), who were in charge of certain major activities, e.g., marking and felling of trees. These were usually leading citizens, often members of families with a vested interest in the forest (e.g., coopers), who held the position for an average of eight years. Sometimes they provided deputies to do the actual work.

Then there was the mayor ( Burgermeister); in Leonberg, you needed his say-so in order "to remove tree stumps, remove lying or dead woods . . . to cut rods, and to drive the pigs into the woods for pannage" (grazing on acorns).

Finally, there were the town's wood wardens, who actually policed the property. Trespassers could be brought before the bailiff ( Schultheiss) of the village court.

A balance had to be struck by each community with respect to the use of land: as farmland (supplying vegetables and grains), as pasture (supplying meat and milk, as well as manure to restore the fertility of the farmland), and as forest (supplying fuel, and the raw material for making buildings and wooden goods)(Warde 53). The latter uses weren't mutually exclusive; pasture use of woodland was extensive. The woodland of a community was usually on its outskirts (since the forest didn't require constant care) or on steep slopes unsuitable for plowing. (Warde 75).

About 70% of the wood was harvested from forest managed as "coppice with standards" ( Mittelwald). To control harvesting, some forests were divided into compartments, harvested cyclically. The most common cycle was sixteen years, but the range was 8-40. The village of Renningen, in the 1560s, had 23 compartments, each 17 morgens (one morgen=0.3316 hectares). Compartmentalization was most common for commune forests, less so for ducal ones. Nonetheless, over 80% of woodland would be earmarked to be cut at a particular time. (Warde 76-7, 235-7).

The forest had a traditional schedule. December and January were the months in which the foresters marked wood as suitable for special uses. The trees were chopped down in February, March and perhaps April (in Munklingen and Leonberg, the cutting season ended on St. George's Day, April 23). This was late enough so that the wood wasn't frozen, but before the sap rose, weakening the wood. The wood sales were done by May. During the summer, the forest officials inspected the forest and chased poachers, handing in their reports in August. There could be a second cutting season in the fall, after St. Edigius' Day (September 1) and before the winter freeze. There was also more surveying, and selling of shipment of wood, in the autumn. (Warde, 78-9).

In general, cutting was frequent enough so that mature stands were relatively rare. Bauholz (building wood) occupied only 14% of the woodland (238). A 1495 ducal ordinance complains of "the great shortage of wood for fuel and building." (175). It may have been the first such official complaint, but it was definitely not the last. Over time, exports of wood declined, and residents who once were allotted free firewood found they had to pay for it (244). Wood sales dropped from about 425 klafter (1 klafter=3.386 cu. m. = 144 cu. ft.) in 1580 to less than 25 in 1630 (244-5). It is rather likely that the wood extracted from the forest exceeded the "mean annual increment."

The town of Gebersheim, with 100 hectares of woodland, sold 18 trees a year in 1630-1, 108 in 1632, 45 in 1633 and 115 in 1634. It seems pretty clear that they were selling off mature trees for ready cash, at a non-sustainable level. (260-1)

There are two key points to remember about the economic role of forests:

—they are a renewable resource

—for most tree species, the renewal is very slow.

The average age of a live oak ( Quercus virginiana) when cut was 75-100 years old. In nature, there are two to three large trees per acre. (Wood, 55). Of course, there are trees which mature quickly. Willow, which can be used in basket-making, provides a return in ten to twelve years. Some poplars take only twenty to thirty years to mature. (Baker 83). Birch, aspen, alder and larch are also rapid growers (Fernow 61-2).

Modern forestry emphasizes "sustained yield" management—that is, the average annual harvest is equal to the average annual growth. Bear in mind that in the short-term, we will be asking the citizens of the USE to harvest less timber. If we haven't educated the people as to why this is important—and if they aren't willing to take a long-term view—then either they will flout the new forestry law, or, if we enforce it, show their disagreement in other ways.

I am not very satisfied with the encyclopedia descriptions of forestry methods. However, I think it reasonable to expect that Gordon Alexander would be familiar with the very basic silviculture principles which I set forth below.